TO MAKE A GOOD FRAMEWORK FOR FILLING IN MISSING BONE, MIX AT LEAST 30 PERCENT PULVERIZED NATURAL BONE WITH SOME SPECIAL MAN-MADE PLASTIC AND CREATE THE NEEDED SHAPE WITH A 3-D PRINTER. THAT’S THE RECIPE FOR SUCCESS REPORTED BY RESEARCHERS AT THE JOHNS HOPKINS UNIVERSITY IN A PAPER PUBLISHED APRIL 18 ONLINE IN ACS BIOMATERIALS SCIENCE & ENGINEERING.

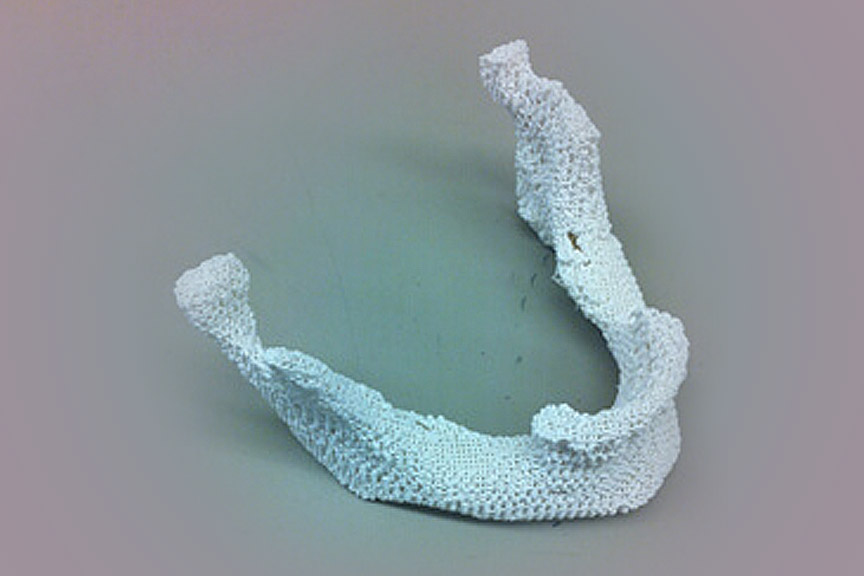

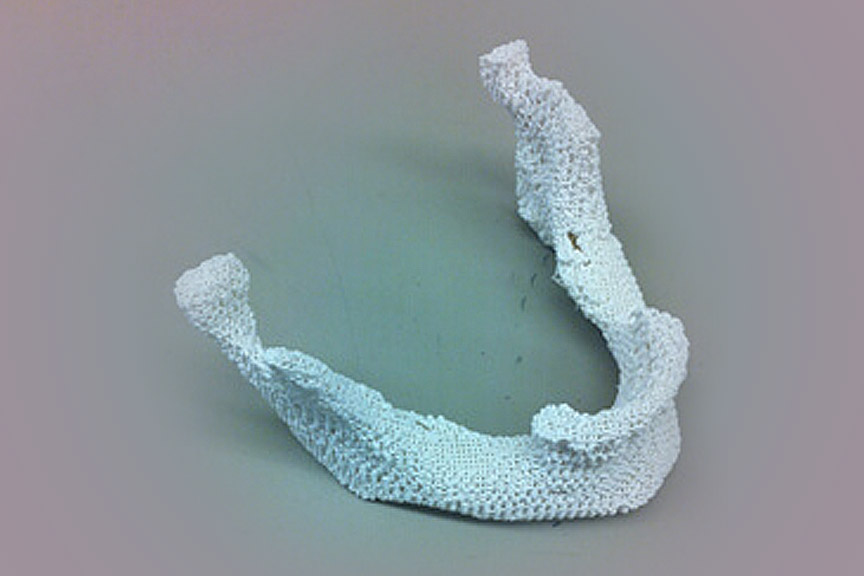

A Sample 3-D Printed Scaffold That Matches The Lower Jaw Of A Female Patient.

Each year, the Johns Hopkins scientists say, birth defects, trauma or surgery leave an estimated 200,000 people in need of replacement bones in the head or face. Historically, the best treatment required surgeons to remove part of a patient’s fibula (a leg bone that doesn’t bear much weight), cut it into the general shape needed and implant it in the right location. But, according to Warren Grayson, Ph.D., associate professor of biomedical engineering at the Johns Hopkins University School of Medicine and the report’s senior author, the procedure not only creates leg trauma but also falls short because the relatively straight fibula can’t be shaped to fit the subtle curves of the face very well.